EnWaRec follows a holistic approach, combining different technologies, sensors and tools to achieve energy and water recovery targets. Within this approach, the following key technologies are being developed:

Technologies & Innovation

- Home

- Technologies & Innovation

EnWaRec's

Technologies & Innovation

-

Technologies

-

Innovation

HIDDEN

HIDDEN

• HEAT EXCHANGER

Waste heat recovery with non-clogging heat exchanger.

Further details:

• on the design and operation will be reported in Deliverable D4.1 and

• on dimensions, efficiency and reuse concepts will be documented in Deliverable D4.6, which are not publicly available due to confidentiality restrictions.

• HIGH TEMPERATURE HEAT PUMP

Concept for waste heat reuse by high temperature heat pump for steam production and sludge drying.

Further details on design and reuse concepts will be reported in Deliverable D4.2. Due to confidentiality restrictions, these results will not be publicly available.

• MEMBRANE DISTILLATION

Concept of water recovery by membrane distillation.

To prevent distillate contamination with feed, membrane wetting will be limited through membrane preselection. Furthermore, the diffused feed will be caught and discharged separately within the effects. These works will be performed by BFI in cooperation with EvCon GmbH. Further work by BFI will focus on the removal of disturbing compounds causing scaling and abrasion. For abrasive solids removal energy efficient ceramic flat microfiltration membranes will be tested. Scaling compounds can be removed by softening. Simultaneous softening and filtration will be developed for pretreatment on basis of the wastewater properties. Further details on design and application of membrane distillation will be reported in Deliverable D4.3. Due to confidentiality restrictions, these results will not be publicly available.

To achieve the described objectives, a holistic approach, combining the different technologies, measurements and tools is necessary.

HIDDEN

HIDDEN

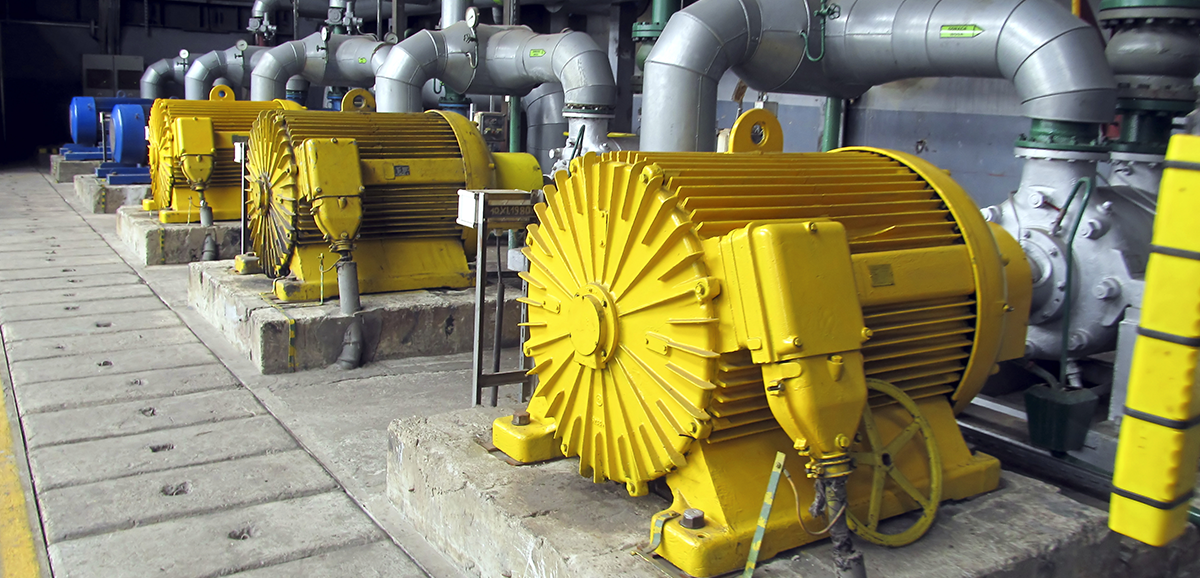

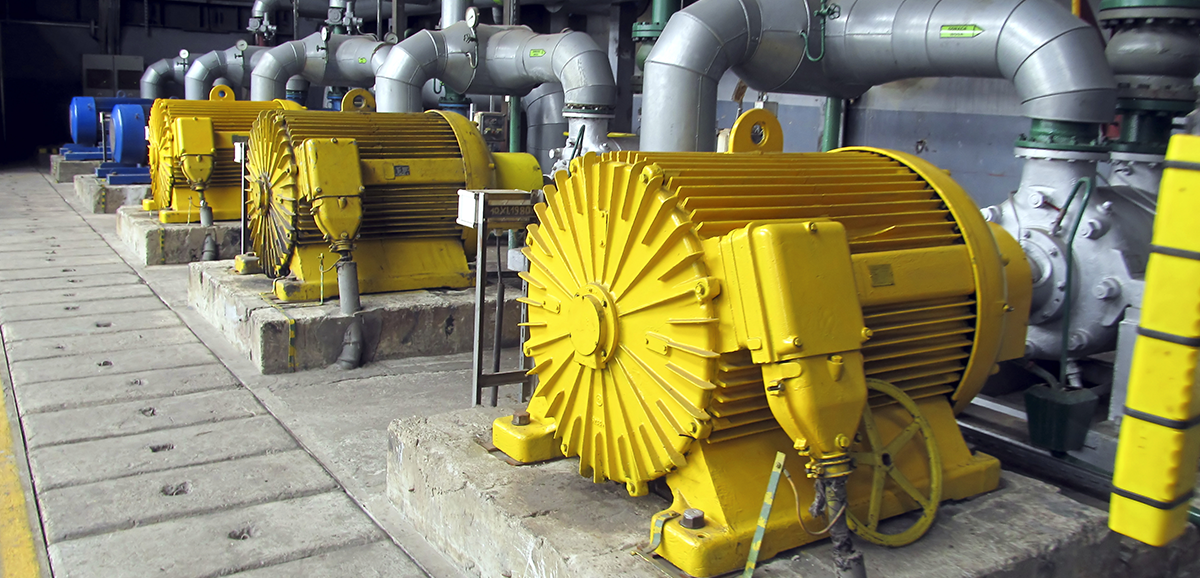

• MICRO TURBINES

Concept for hydropower recovery by micro-turbine to produce electricity.

Further details on design and application of micro turbines will be reported in Deliverable D4.4. Due to confidentiality restrictions, these results will not be publicly available.

• COATINGS

Objectives:

• Coatings for corrosion and wear protection of heat exchanger surfaces, micro turbine parts and nozzles.

• Thermal stable chemicals for reliable water conditioning at temperatures up to 80°C.

• Suitable corrosion and scaling measurements for a tailored chemical dosing as mandatory step for an ensured heat and energy recovery.

Further details will be developed in Work Package 3: Development of suitable scaling and corrosion protection.

• SMART MONITORING & SOFTWARE TOOLS

Development of smart monitoring concepts and tools for the energy and water recovery techniques.

Further details on smart monitoring and software tools will be reported in Task 4.5. Due to confidentiality restrictions, these results will not be publicly available. Motivation: Need for stable operation and flexible adjustment of energy and water recovery techniques to the fluctuating steel production/ circuit operation mode. Aspired results: Smart management concept for integration into the monitoring tool of heat and water recovery systems. Rule-based models for performance stabilisation, predictive maintenance and failure management.

For this, technologies and novel approaches as well as concepts added by fundamental research will be combined at technological, economic and environmental levels.

HIDDEN

HIDDEN

• HEAT EXCHANGER

Waste Heat Recovery with non-clogging Heat Exchanger.

Further details:

• on the design and operation will be reported in Deliverable D4.1 and

• on dimensions, efficiency and reuse concepts will be documented in Deliverable D4.6, which are not publicly available due to confidentiality restrictions.

• HIGH TEMPERATURE HEAT PUMP

Concept for waste heat reuse by high temperature heat pump for steam production and sludge drying.

Further details on design and reuse concepts will be reported in Deliverable D4.2. Due to confidentiality restrictions, these results will not be publicly available.

• MEMBRANE DISTILLATION

Concept of water recovery by membrane distillation.

To prevent distillate contamination with feed, membrane wetting will be limited through membrane preselection. Furthermore, the diffused feed will be caught and discharged separately within the effects. These works will be performed by BFI in cooperation with EvCon GmbH. Further work by BFI will focus on the removal of disturbing compounds causing scaling and abrasion. For abrasive solids removal energy efficient ceramic flat microfiltration membranes will be tested. Scaling compounds can be removed by softening. Simultaneous softening and filtration will be developed for pretreatment on basis of the wastewater properties. Further details on design and application of membrane distillation will be reported in Deliverable D4.3. Due to confidentiality restrictions, these results will not be publicly available.

• MICRO TURBINES

Concept for hydropower recovery by micro-turbine to produce electricity.

Further details on design and application of micro turbines will be reported in Deliverable D4.4. Due to confidentiality restrictions, these results will not be publicly available.

• COATINGS

Objectives:

• Coatings for corrosion and scaling protection of heat exchanger surfaces, micro turbine parts and nozzles.

• Thermal stable chemicals for reliable water conditioning at temperatures up to 80°C.

• Suitable corrosion and scaling measurements for a tailored chemical dosing as mandatory step for an ensured heat and energy recovery.

Further details will be developed in Work Package 3: Development of suitable scaling and corrosion protection.

• SMART MONITORING & SOFTWARE TOOLS

Development of smart monitoring concepts and tools for the energy and water recovery techniques.

Further details on smart monitoring and software tools will be reported in Task 4.5. Due to confidentiality restrictions, these results will not be publicly available. Motivation: Need for stable operation and flexible adjustment of energy and water recovery techniques to the fluctuating steel production/ circuit operation mode. Aspired results: Smart management concept for integration into the monitoring tool of heat and water recovery systems. Rule-based models for performance stabilisation, predictive maintenance and failure management.

To achieve the described objectives, a holistic approach, combining the different technologies, measurements and tools is necessary.

HIDDEN

For this, technologies and novel approaches as well as concepts added by fundamental research will be combined at technological, economic and environmental levels.

Micro-turbine by Easy Hydro for hydropower recovery in industrial water circuits — part of EnWaRec’s holistic approach for energy and water recovery in the European steel industry.